The Mobile EDI Implementation Guide: How Supply Chain Teams Can Achieve Real-Time Data Exchange on Smartphones and Tablets in 2025

Mobile EDI implementation represents a paradigm shift for supply chain teams operating in an increasingly connected world. Mobile EDI enables businesses to exchange data using mobile devices such as smartphones and tablets, helping businesses increase efficiency, reduce errors, and improve collaboration with partners and suppliers. With mobile-enabled EDI dashboards and low-code platforms becoming more popular, these tools let business people set up connectors, keep track of transactions, and fix problems without a lot of technical knowledge.

Understanding Mobile EDI: The Next Evolution in Supply Chain Data Exchange

Mobile EDI transforms how field teams interact with traditional EDI systems by providing real-time access to critical business documents through smartphones and tablets. Unlike desktop-bound EDI systems that require users to be physically present at workstations, mobile EDI allows users to send and receive EDI transactions via mobile devices, with mobile devices such as smartphones and tablets changing how businesses interact with trading partners and companies starting to develop applications to help mobilize their supply chain.

The technology leverages existing cloud-based EDI infrastructure to deliver transaction data directly to mobile devices. This approach enables warehouse managers, logistics coordinators, and field service teams to access purchase orders, shipping notices, and inventory updates while moving throughout their facilities or visiting customer locations.

Key capabilities include real-time document processing, barcode scanning integration, and push notifications for critical transactions. Because corporate apps are now becoming popular, it's only a matter of time before you can download an EDI-related mobile application from the app stores. The mobile interface simplifies complex EDI processes into intuitive workflows that non-technical users can master quickly.

The Business Case for Mobile EDI in Modern Supply Chains

The demand for accurate, real-time information throughout the supply chain has created mobile computing for manufacturing. Supply chain teams operating in fast-paced environments need instant access to transaction data to make informed decisions without delays that could impact customer deliveries or inventory accuracy.

Consider a distribution center manager who receives an urgent call about a delayed shipment. With mobile EDI, they can immediately access the advance shipping notice (ASN) on their smartphone, check the carrier status, and update the customer within minutes rather than returning to their desk. This responsiveness directly translates to improved customer satisfaction and reduced operational friction.

The ROI calculations are compelling. Traditional EDI implementations often require dedicated staff to monitor transactions at fixed terminals. Companies employing digital SCM solutions have seen cost-reductions upward of 20%. Mobile EDI extends this efficiency by enabling the same personnel to handle multiple locations or tasks simultaneously while maintaining real-time visibility into critical processes.

Transportation management integration amplifies these benefits. Modern TMS platforms like Cargoson, MercuryGate, and Descartes now offer mobile capabilities that complement EDI workflows. When a carrier updates delivery status through their mobile TMS app, the information automatically flows through EDI channels to update inventory systems and trigger customer notifications.

Mobile EDI Architecture and Technology Requirements

Successful mobile EDI implementation requires a robust cloud-based infrastructure that can handle both traditional batch processing and real-time mobile interactions. Cloud-based EDI eliminates the need for businesses to invest in hardware and software infrastructure and provides greater scalability, reliability, and security, with businesses able to access EDI solutions from any location with an internet connection.

The architecture typically involves three layers: the mobile application interface, cloud-based EDI processing engines, and integration APIs that connect to existing ERP systems. Security becomes paramount when extending EDI access to mobile devices, requiring multi-factor authentication, encrypted data transmission, and device management policies.

Network connectivity presents unique challenges. Mobile platforms must be designed to operate seamlessly even in low or no internet connectivity situations, ensuring uninterrupted operations and automatic data synchronization upon connection restoration. This offline capability proves essential in warehouse environments where Wi-Fi coverage may be inconsistent or in field locations with limited cellular service.

Integration with existing EDI infrastructure requires careful planning. Most organizations cannot replace their entire EDI system overnight, so mobile solutions must work alongside legacy VAN connections and on-premise software. This hybrid approach allows gradual migration while maintaining critical business operations.

Step-by-Step Mobile EDI Implementation Process

Begin your mobile EDI implementation with a comprehensive assessment of current workflows and user requirements. Document which transactions would benefit most from mobile access, focusing on high-frequency processes where real-time updates provide maximum value. Inventory management, order processing, and shipping confirmations typically offer the best ROI for initial mobile deployment.

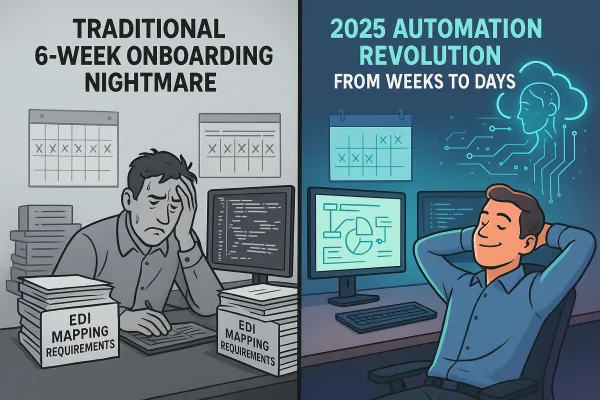

Partner onboarding requires special attention in mobile environments. Your EDI solution should simplify and accelerate onboarding, especially if you work with multiple supply chain partners. Mobile-friendly onboarding processes should include simplified testing procedures and automated validation routines that don't require partners to understand complex technical specifications.

ERP integration testing becomes more complex with mobile components. Your implementation team must validate that mobile transactions properly update inventory levels, trigger reorder points, and maintain audit trails across all connected systems. This includes testing various network conditions, device types, and concurrent user scenarios.

User training shifts from traditional classroom sessions to bite-sized, workflow-specific modules delivered through the mobile app itself. Interactive tutorials that guide users through actual transactions prove more effective than theoretical presentations. Include error handling scenarios so users understand how to respond when mobile connectivity issues arise.

Mobile EDI Platforms and Vendor Comparison

The mobile EDI landscape includes established providers adapting their platforms for mobile access alongside newer companies built specifically for mobile-first workflows. Cleo Integration Cloud (CIC), is a cloud-based integration platform solution that offers customers innovative EDI integration capabilities and features that are routinely updated.

SPS Commerce has invested heavily in mobile capabilities, offering smartphone apps that provide visibility into transaction status and exception management. Their mobile interface integrates with their vast network of pre-mapped trading partner connections, making it particularly attractive for retailers managing hundreds of supplier relationships.

TrueCommerce focuses on managed services with mobile dashboards that provide oversight without requiring deep technical knowledge. However, TrueCommerce does not provide full self-service capabilities, with global mapping changes that must be performed by TrueCommerce, and customers don't own the maps they create when working with TrueCommerce.

For organizations requiring TMS integration alongside EDI mobility, consider platforms that work seamlessly with solutions like Cargoson, nShift, and Transporeon. These integrations enable comprehensive supply chain visibility from initial order processing through final delivery confirmation.

Orderful represents the newer generation of mobile-first EDI providers. Orderful is a modern, cloud-native EDI platform built for speed, scalability, and developer-friendliness, offering an API-first approach and streamlined onboarding for supply chain teams looking to move beyond legacy EDI systems.

Security and Compliance Considerations for Mobile EDI

Security is a top priority for businesses that rely on EDI, with stronger security protocols being implemented across the board in 2025, as cyberattacks continue to evolve and businesses must protect sensitive data with EDI transactions often involving confidential information.

Mobile device security requires a layered approach beyond traditional network firewalls. Device enrollment policies should mandate screen locks, automatic session timeouts, and remote wipe capabilities for lost or stolen devices. Application-level security must encrypt all EDI data both in transit and at rest on mobile devices.

Compliance considerations vary by industry but generally require maintaining detailed audit trails of who accessed which documents when and from what location. Healthcare organizations implementing mobile EDI must ensure HIPAA compliance, while financial services companies need to meet SOX requirements. Mobile access actually enhances compliance in many cases by providing more granular activity logging than traditional desktop systems.

Encryption and multi-factor authentication are becoming standard in EDI systems, with these security measures ensuring that data stays protected even as threats grow more sophisticated. Mobile implementations should include biometric authentication where available and certificate-based device authentication for enhanced security.

Real-World Mobile EDI Use Cases and Success Stories

Warehouse operations represent one of the most successful mobile EDI applications. Mobile applications provide the ability to perform shop floor and warehouse transactions from any location in a facility using wireless radio frequency devices that can be hand-held, wearable, ring scanner systems, and lift truck mounted, with data entry functions both manually and with a barcode scanner.

A major automotive parts distributor implemented mobile EDI to enable their receiving team to process advance shipping notices directly on handheld devices while unloading trucks. The system automatically updates inventory levels and generates discrepancy reports when received quantities don't match the EDI documents. This eliminated the previous workflow requiring workers to return to fixed terminals between each pallet verification.

Transportation and logistics companies benefit significantly from mobile EDI integration with TMS platforms. When carriers use mobile TMS solutions like Cargoson or Transporeon to update delivery status, the information flows through EDI channels to automatically update customer systems and trigger billing processes. This integration eliminates manual data entry and reduces delivery confirmation delays from hours to minutes.

Manufacturing environments utilize mobile EDI for production reporting and material consumption tracking. Mobile platforms allow recording ingredient consumption, product and byproduct yields, and resource usage during batch production, enabling real-time production batch updates on the shop floor and minimizing the data entry burden on operators while increasing production data accuracy.

Field service applications demonstrate mobile EDI's versatility beyond traditional supply chain roles. Service technicians can access parts availability through mobile EDI connections to supplier systems, automatically generate purchase orders for required components, and receive shipping confirmations directly on their mobile devices while at customer locations.

A leading retail chain integrated a mobile SCM solution to manage its extensive inventory and distribution network, achieving a 20% reduction in inventory costs through real-time inventory monitoring and demand forecasting, 30% faster order fulfillment through automated workflows and immediate data access, and enhanced customer satisfaction through faster deliveries and better communication.

The future of mobile EDI extends beyond simple transaction access. Future trends in mobile supply chain management include the integration of AI, IoT, and advanced analytics, promising increased automation and improved decision-making. Organizations implementing mobile EDI today position themselves to leverage these emerging technologies as they mature, creating competitive advantages through enhanced supply chain visibility and responsiveness.